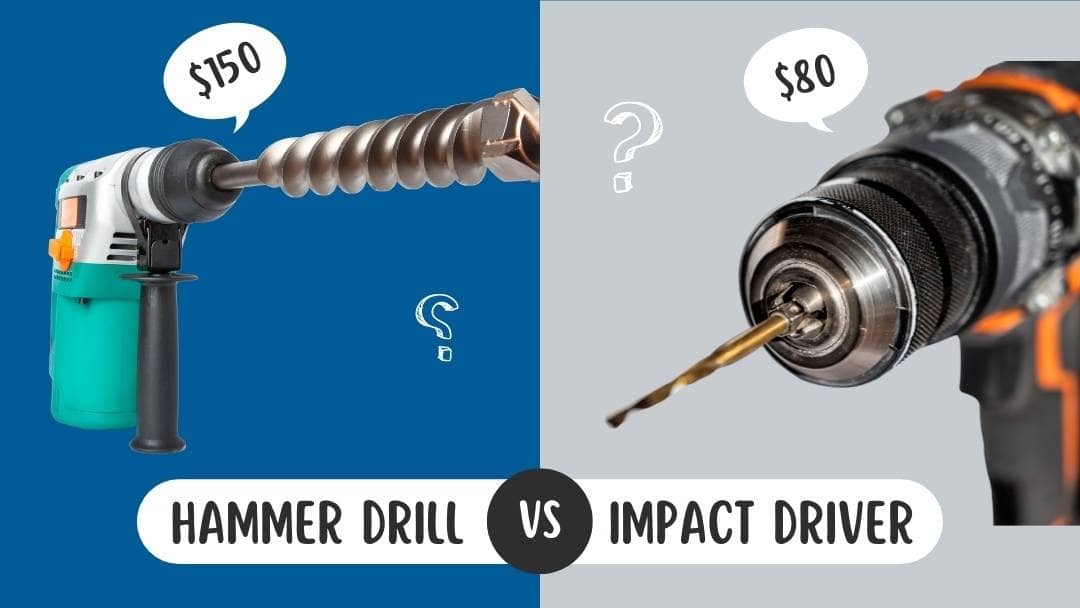

Concrete is brittle and holes are typically unsalvageable if blown out. That being, don't use a power tool to run fasteners in concrete. There are attachments that allow you to use a rotary hammer/SDS with normal drive bits, it's a sleeve that goes over the SDS bit and has a drywall screw style ph2 that will physically back out of the screw when it's flush with the material surface. It the holes you're drilling are 1/4" or smaller, a hammer drill/driver will generally do you fine and last. Rotary hammer/SDS (what I believe you've confused for hammer drill)- has an entire separate percussive mechanism that repeatedly hammers on the back of the chuck creating strong forward shock while drilling, and is entirely purposed for just concrete drilling. Hammer drill/driver- bounces the chuck and drill bit off of a bumpy gear inside, causes forward vibration to help in small/light duty concrete drilling Impact driver-smacks the bit rotationally, extra help turning things Unlike drywall, patching holes in concrete is far more laborious an endeavor. If you want one tool - then like other posts have said - I'd recommend getting a hammer drill that has the option to turn the hammer function off so you can use it like a regular drill-driver if needed.īut a separate question begs asking: check with your apartment complex / landlord that they're OK with you boring holes in concrete walls. While it's possible to drill into concrete without a hammer drill, it will take forever, and may cause you to regret multiple life decisions leading up to that point. Using a drill-driver to drill into concrete puts the "work" of drilling at the end of the drill bit, so it has to shave concrete away and extract it via the flutes. Another way to visualize it - if you're holding a chisel and hammering into wood, that's the direction the hammer is working on a hammer drill. Hammer drills are good for drilling into stubborn material, because the hammering action works into the material, breaking it up and making it easier for the bit to remove. Instead of a head that rotates the drill bit into a surface, hammer drills have an impact mechanism that breaks down hard materials by continuously and rapidly. So the hammer is impacting the bit in the direction you want the bit to go. The hammer drill hammers longitudinally (think "along the tool").

That's why they're good for driving screws into stubborn materials, because the impact acts along the path of resistance - namely, the act of turning the screw radially into the material.

The impact driver hammers radially (think "along the circle's path"). This might be overkill, but while we're doing the whole "learning" thing, here's another way to think about it.Īn "impact driver" and "hammer drill" both have a hammering mechanism - but that mechanism acts in different directions.

0 kommentar(er)

0 kommentar(er)